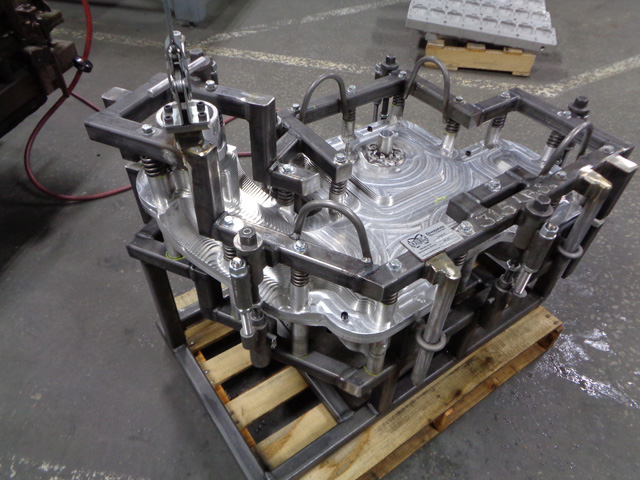

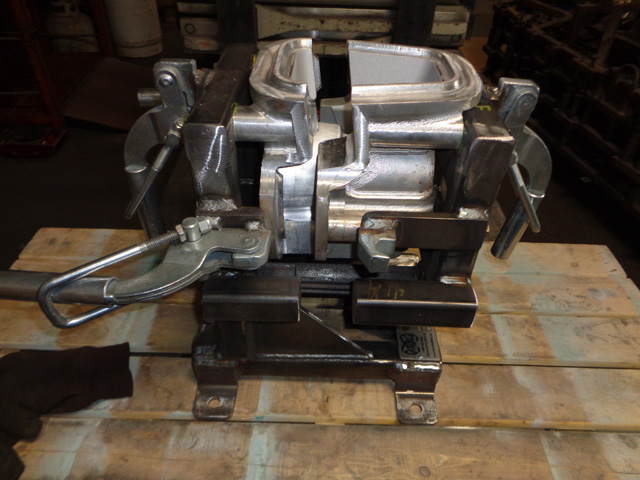

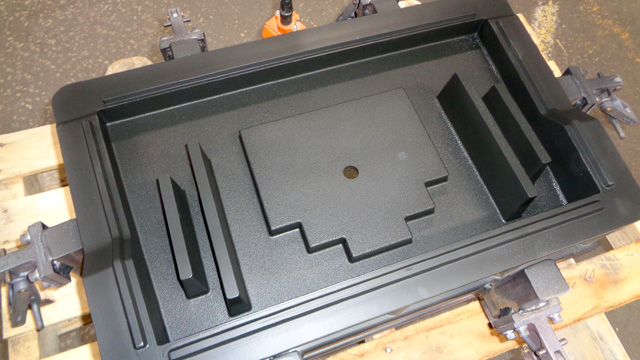

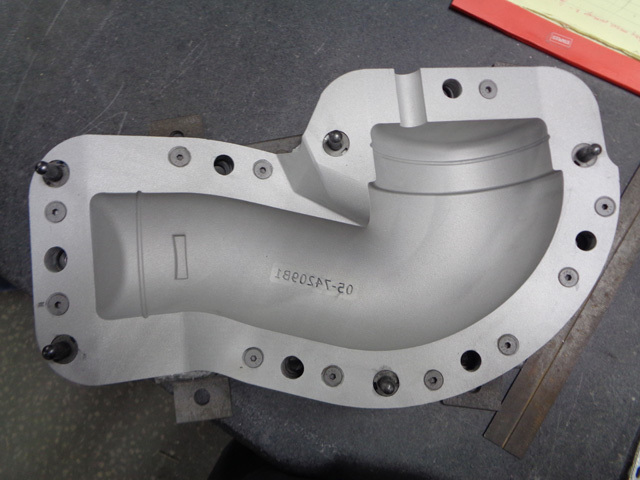

CNC Aluminum Molds

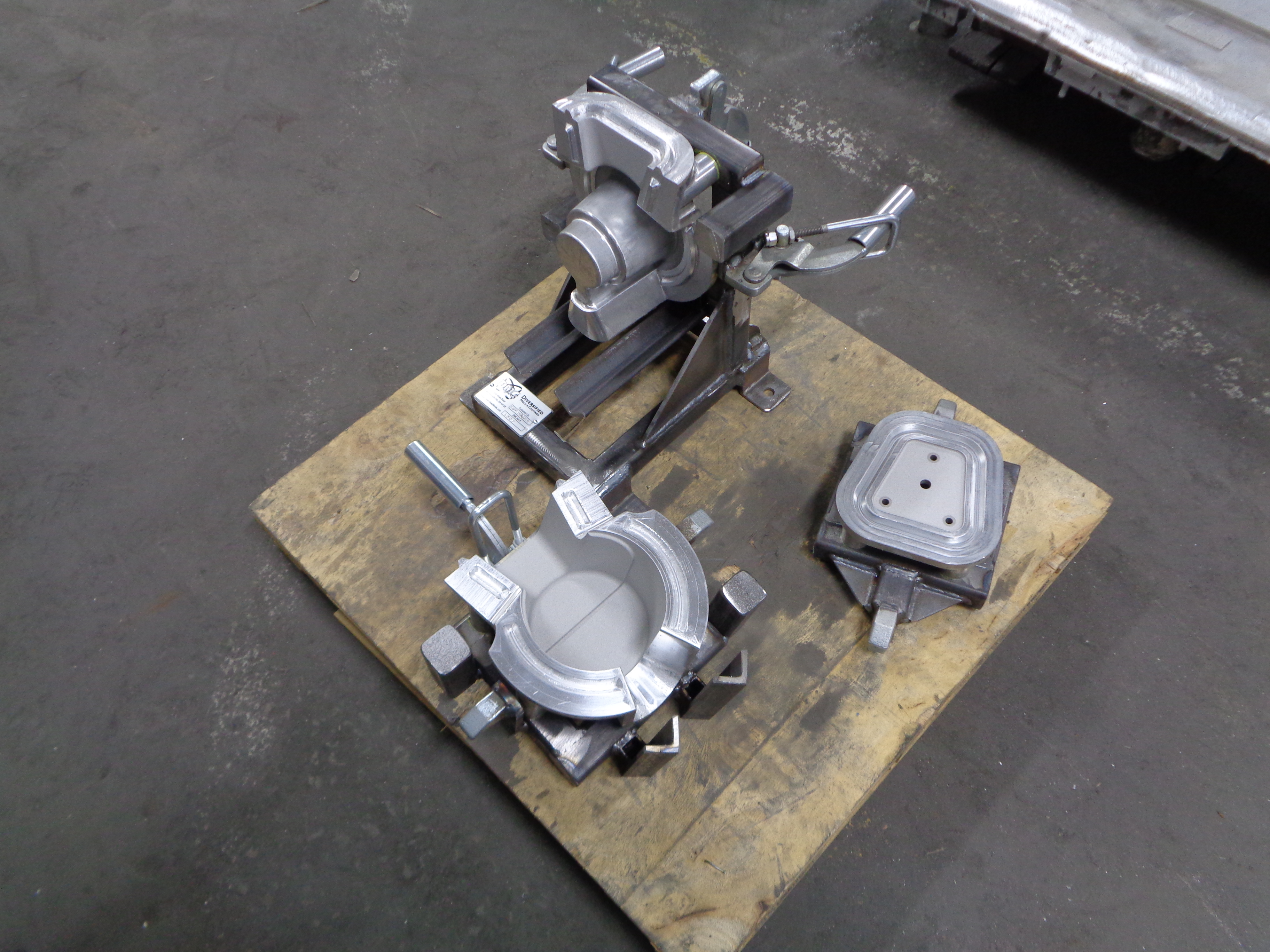

Surface finishing, dimensional accuracy, expedited lead times; all of these factors are what make CNC tooling a great option when deciding what type of mold you should consider.

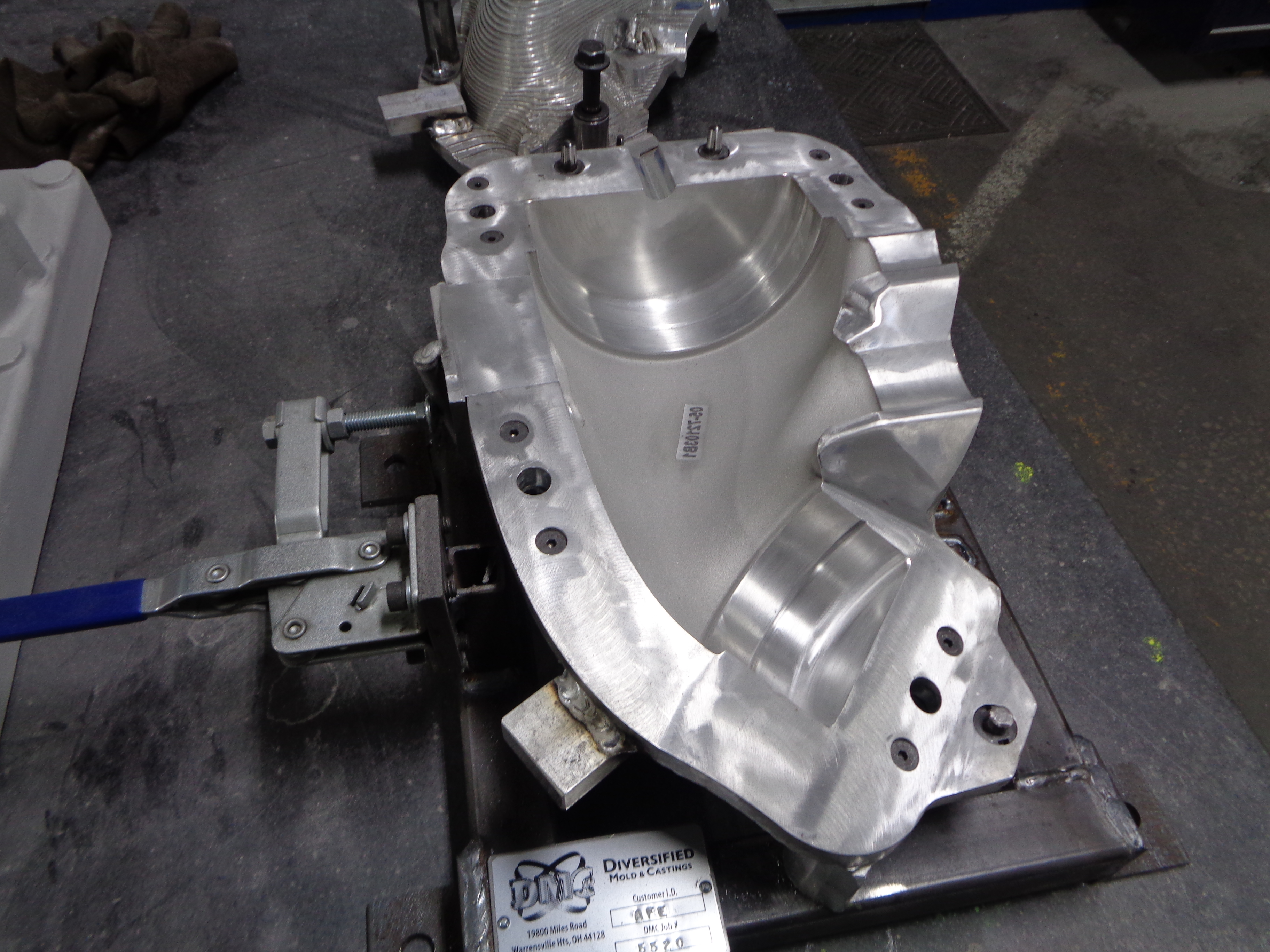

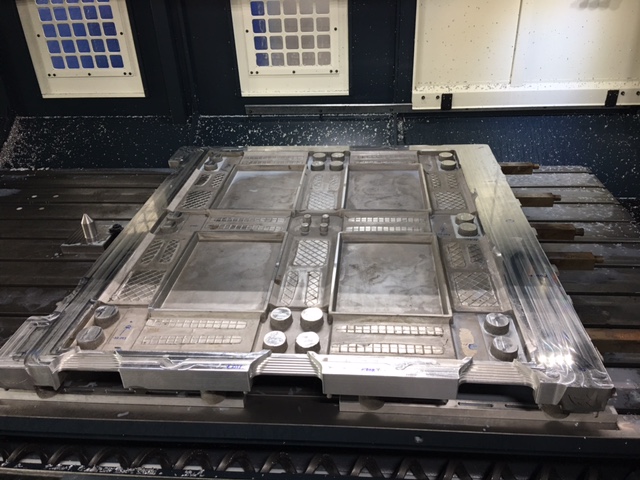

CNC molds are the most precise mold building technique. This type of tooling utilizes the customer supplied 3D data to create a mold which is fully machined out of aluminum billet. As the cost of this type of tooling becomes more affordable, it is quickly gaining traction and may become the preferred type of tooling for small to medium size molds in the near future.

Diversified has two CNC machines in-house; our VMC with the ability to cut small to medium sized molds and our large bridge mill with a cutting capacity of 120" x 60" x 30".

- Extremely dimensionally accurate

- No pattern required

- No tooling required

- Mold cavity that has conforming surfaces with no casting defects

- Good thermal heat transfer due to the accuracy of the wall thickness and density of the material